浙江贊誠(chéng)生物科技有限公司

ZHEJIANG ZANCHENG LIFE SCIENCES LIMITED

Specializing in the production and management of intermediates and fine chemicals

ZHEJIANG ZANCHENG LIFE SCIENCES LIMITED

Specializing in the production and management of intermediates and fine chemicals

Chemintel Technology

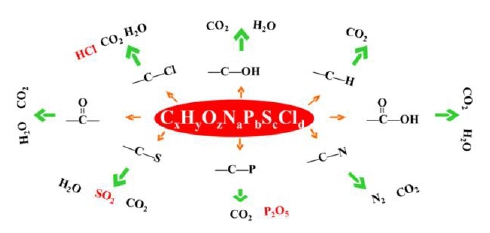

Under the action of the catalyst, the organic matter undergoes an oxygen cleavage reaction with oxygen in the air, and the cracking and oxidation produce a coupling effect. The organic carbon is oxidized to carbon dioxide, and the hydrogen is oxidized to water, thereby completely converting the organic matter into substantially harmless carbon dioxide and water. The principle is as follows:

VOCs Volatile Organic Compounds, according to the definition of the World Health Organization, have a boiling point of 50-250 ° C. The saturated vapor pressure at room temperature exceeds 133.32 Pa. A class of organic substances present in the air in the form of vapor at room temperature is volatile organic compounds (VOCs). ). From the perspective of environmental monitoring, it refers to the general term for non-hydrocarbon detectors detected by hydrogen flame ion detectors, including hydrocarbons, oxygen hydrocarbons, halogenated hydrocarbons, nitrogen hydrocarbons and sulfur hydrocarbons.

The composition of VOCs is complex. There are hundreds of kinds of organic substances that have been purified and tested in the laboratory. According to their chemical structures, they can be further divided into the following categories.

| MO. | VOCs category | Main ingredient |

| 1 | Fat hydrocarbon | Butane, n-hexane |

| 2 | Aromatic hydrocarbons | Benzene, toluene, xylene, styrene |

| 3 | Chlorinated hydrocarbon | Dichloromethane, chloroform, trichloroethane, dichloroethylene, trichloroethylene, carbon tetrachloride |

| 4 | Ketones, aldehydes, alcohols, polyols | Acetone, methyl ethyl ketone, cyclohexanone, methyl isobutyl ketone, formaldehyde, methanol, isopropanol, isobutanol |

| 5 | Ether, phenol, epoxy compounds | Ether, cresol, phenol, ethylene oxide, propylene oxide |

| 6 | Ester, acid compound | Ethyl acetate, butyl acetate, acetic acid |

| 7 | Amine, nitrile compound | Dimethylamide, acrylonitrile |

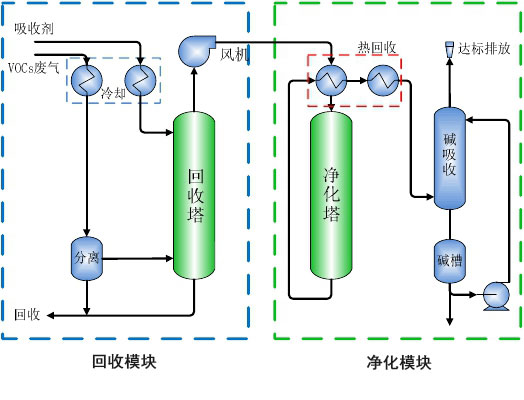

VOCs have a wide variety of exhaust gases and are widely used. We classify VOCs as high concentration (VOCs > 10000mg / cubic meter) and low concentration (VOCs < 10000mg / cubic meter). Most of the VOCs in the exhaust gas are raw materials, intermediate products or products used in the production process. Considering the value of VOCs and the cost of recovery, the high-concentration exhaust gas needs to be recycled, and the low-concentration exhaust gas can be directly purified. For different concentrations and types of VOCs, we have designed two basic unit modules for recovery and purification, which can be used individually or in combination, as shown below:

The condensing and absorbing combination method is used to first cool the VOCs exhaust gas, so that some organic matter forming droplets are separated from the gas, and the remaining gas is again fed into the recovery tower, and is absorbed by the low volatility absorbent. The absorbent preferentially selects the materials present in the raw materials, intermediate products, products and the like used in the production process, and the absorbed materials can be recycled to the production device for recycling. The absorption process adopts an absorption tower with a special structure, the flow rate of the exhaust gas can fluctuate within a wide range, and a small amount of the absorbent can be used to achieve an ideal absorption effect, and has the remarkable advantages of high operational flexibility and high recovery rate.

One-stop purification of VOCs waste gas is carried out by the Oxygen Cracking Process. The VOCs are exchanged with the purified high-temperature exhaust gas, and the VOCs are oxidized after entering the purification tower, and then discharged to the standard. For different types of waste gas, it can also be equipped with alkali absorption equipment for neutralizing and absorbing acid gases generated by the purification of VOCs containing chlorine, nitrogen, sulfur and phosphorus.

① Short process: VOCs waste gas undergoes deep oxidation reaction to produce inorganic products such as carbon dioxide and water. One-stop purification can achieve gas and water discharge standards without secondary pollution.

② Low processing cost: the purification process only needs to introduce the air required for the oxidation reaction, no need to add fuel and provide external heating, and no other power consumption. Take the air volume of 1000m3/h as an example, the running power is about 10KW, and the operation The cost is less than 200 yuan / day.

③ High degree of automation: The whole set is armored and equipped with DCS integrated control system, which can be integrated with the product production equipment and easy to operate and maintain.

④ Safe and reliable operation: The self-developed high-efficiency catalyst has low operating temperature and complete safety equipment and control system for intrinsic safety and long-term stable operation.

BACK

TOP